Multi-Stage Boiler Feed Pump

- A work procedure was written for the vertical stripping and assembly of the BFP.

- KARM were tasked with re-engineering and supplying the required spares for the project.

- Specialist tools were designed and manufactured to help with the stripping procedure.

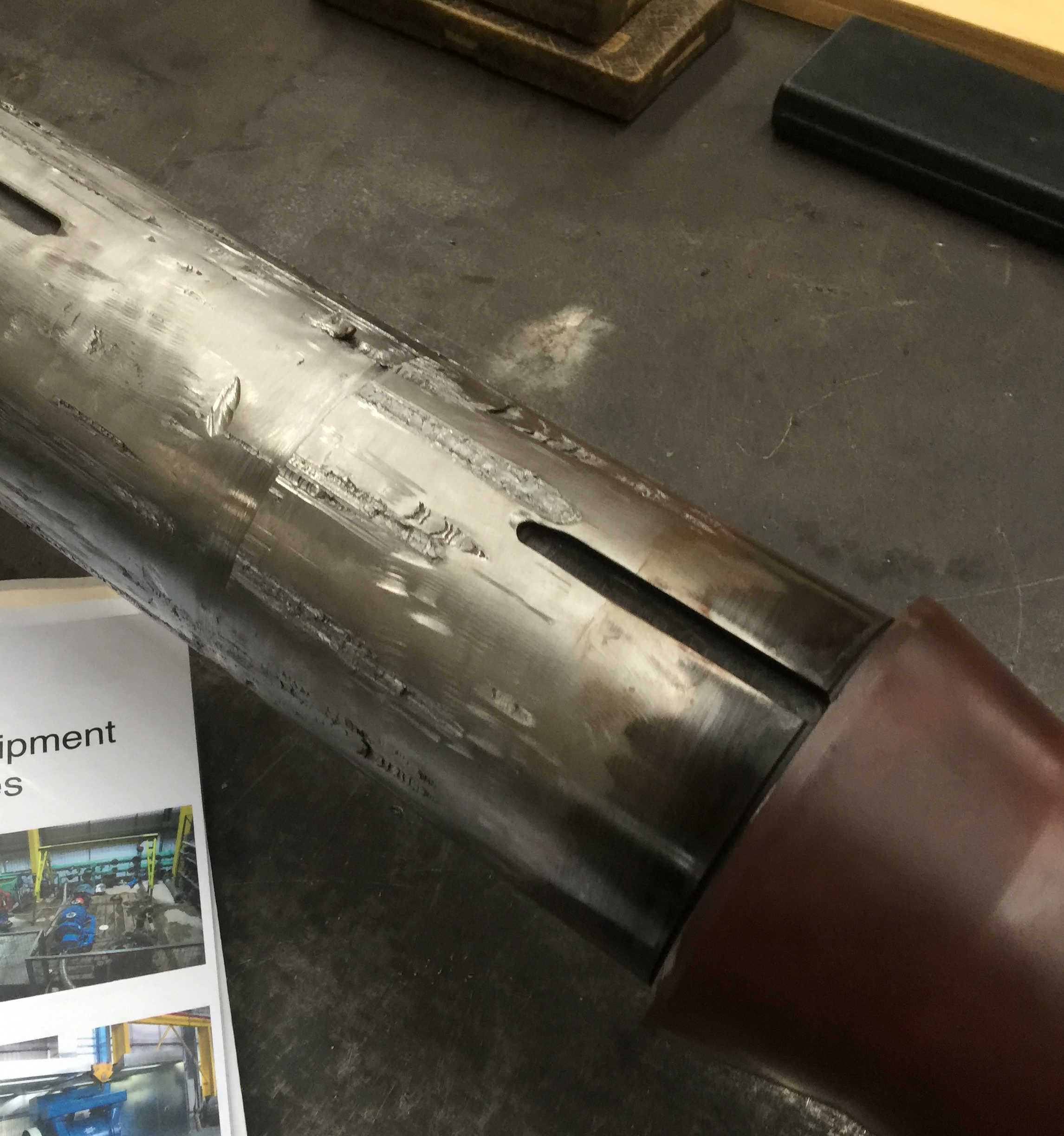

- Damage can be seen on old shaft and 4th stage impeller bore, due to poor design and material selection by the OEM.

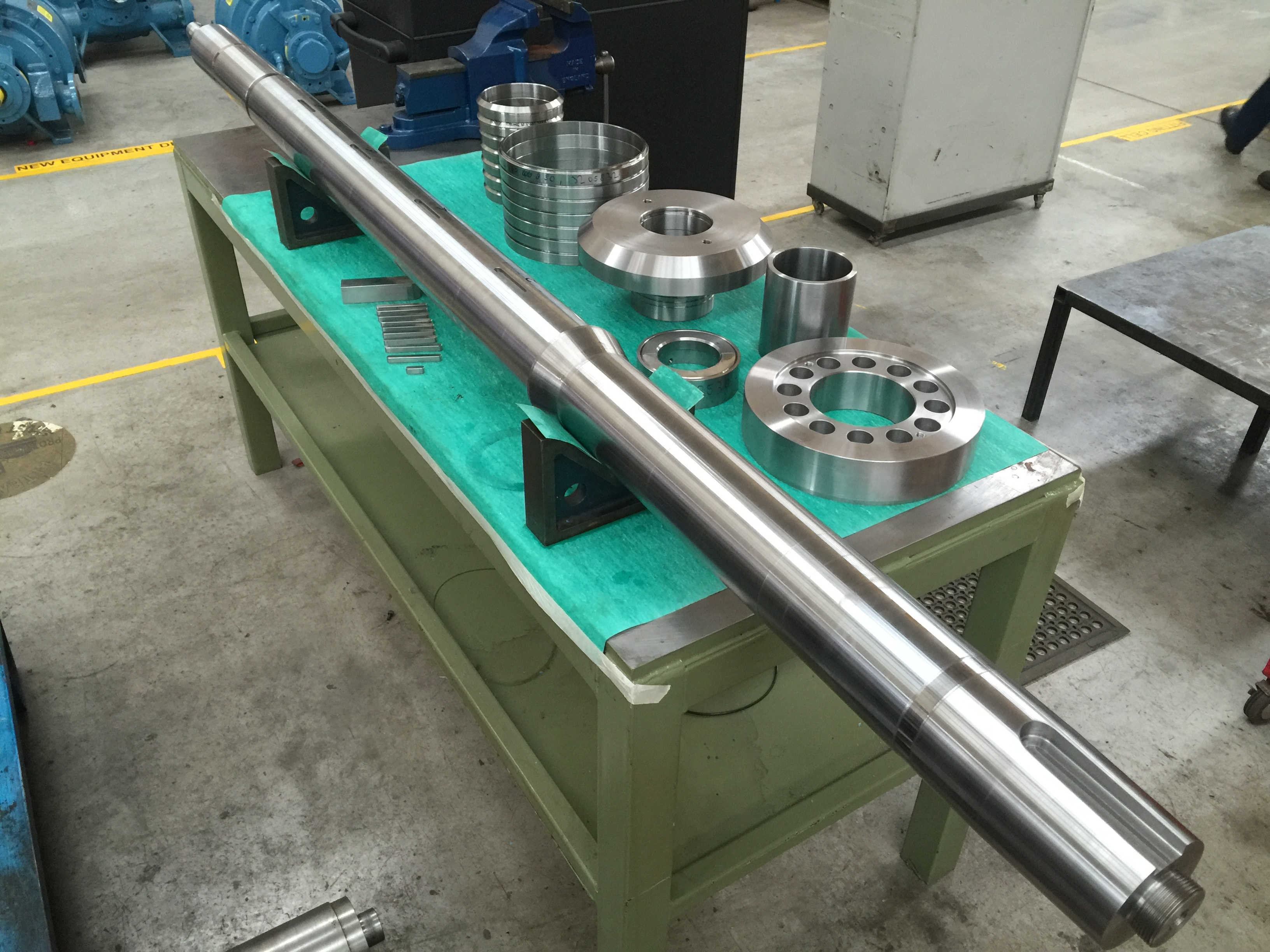

- A modified shaft was manufactured incorporating stepped shoulders and chromed landings to facilitate easier stripping and assembly of the rotor.

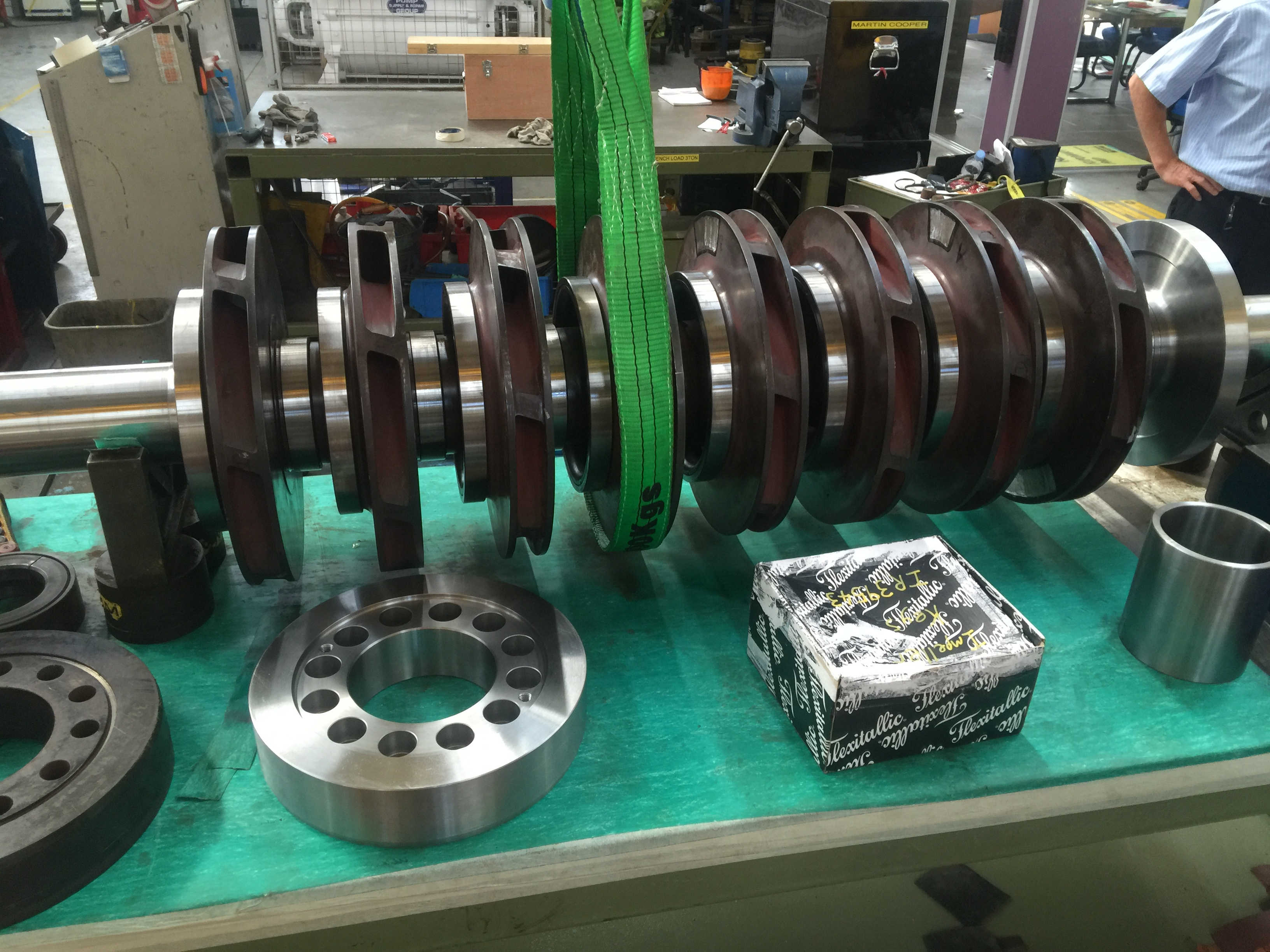

- KARM supplied a new shaft and selection of spares, including; balance discs, wear rings and keys.

- The pump was assembled, pressure and performance tested before being delivered back to the customer.

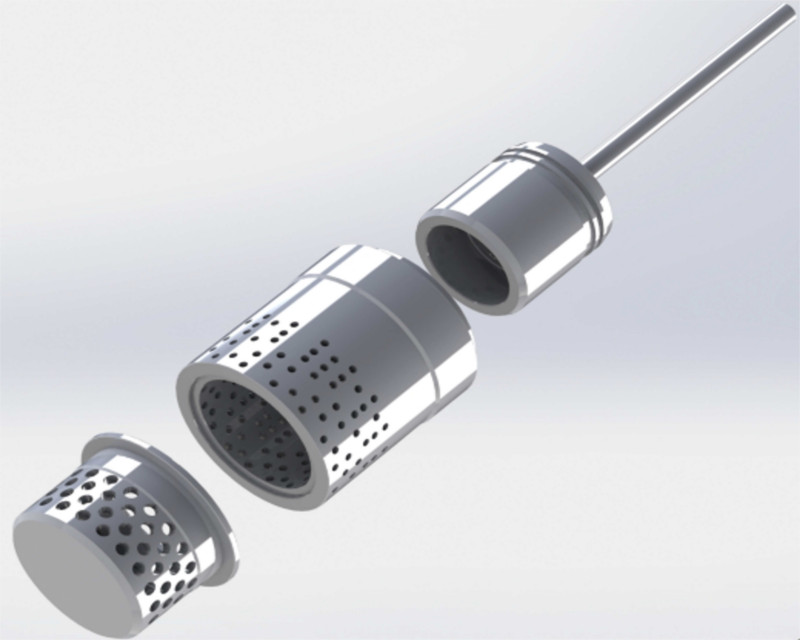

Steam Control Valve

- KARM produced 3D CAD models from used samples.

- Materials and hardness values were identified and verified.

- OEM quoted 14 weeks delivery, KARM delivered new spares back to the customer in 10 days.

Propeller Blade

- Obsolete part, unavailable to purchase.

- Attended site to scan and model blade from damaged sample.

- Using the data captured, the size of the damaged blade was increased to match its original intended design and weight.

- KARM then worked closely with a specialist pattern maker & foundry to manufacturer a new blade from the model and drawing.

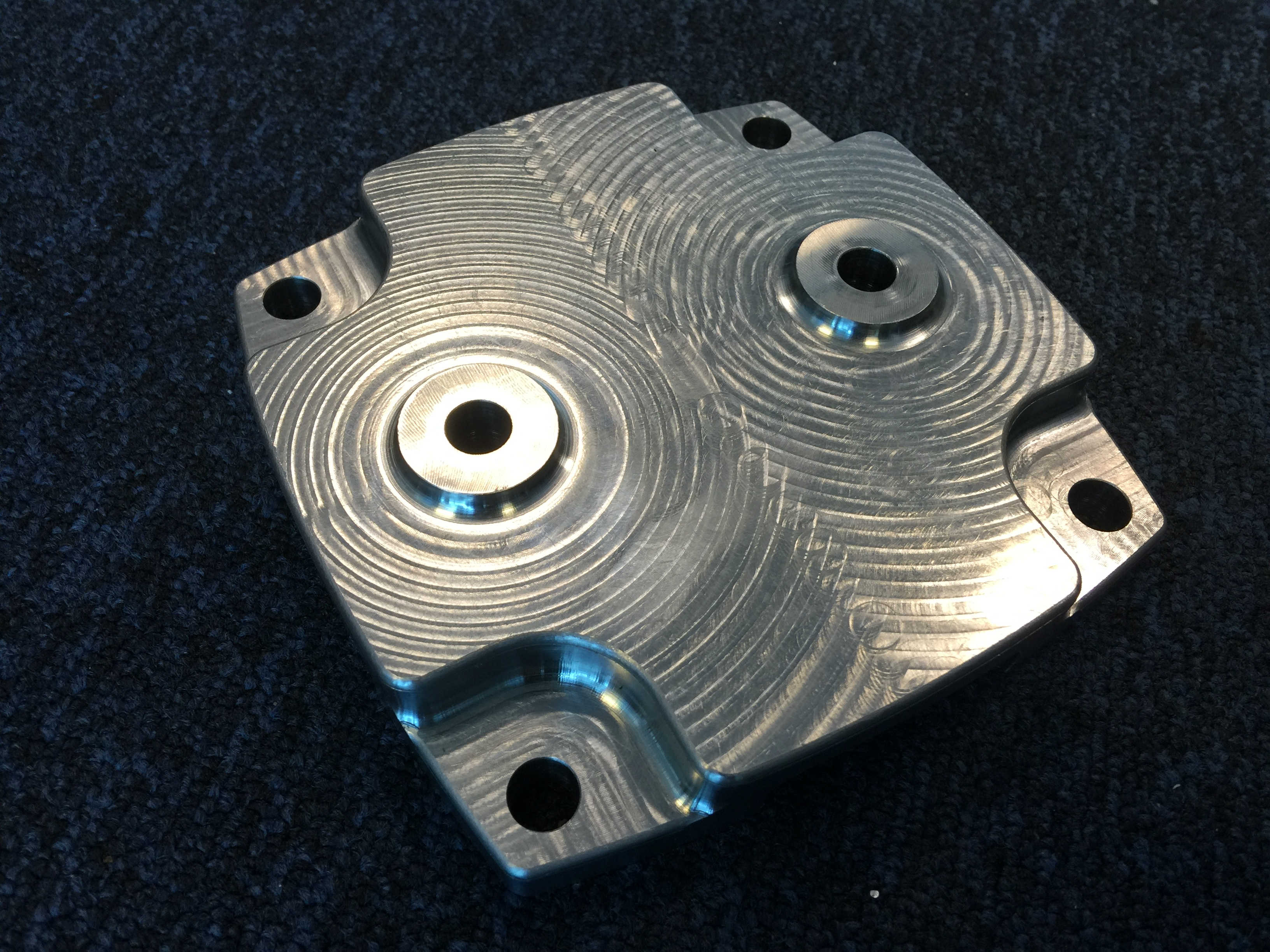

Booster Valve

- KARM were approached by customer to re-engineer obsolete booster valve.

- Valve is in operation in a harsh environment, dispensing bulk powder which is very abrasive.

- Customer was also finding it difficult to source serviceable parts, such as the diaphragm and spring.

- KARM attended site to scan and model worn sample parts.

- All details recorded and engineering drawings produced for each individual part, including spring and diaphragm.

- Original valve was a cast product and in order to minimise costs the new valve was designed to be CNC machined from solid billet. This not only eliminates the need for pattern equipment but also means that the new valves were intrinsically stronger and able to withstand the rigors of life on plant.

- Valves were assembled and painted prior to dispatch, arriving ready for installation.

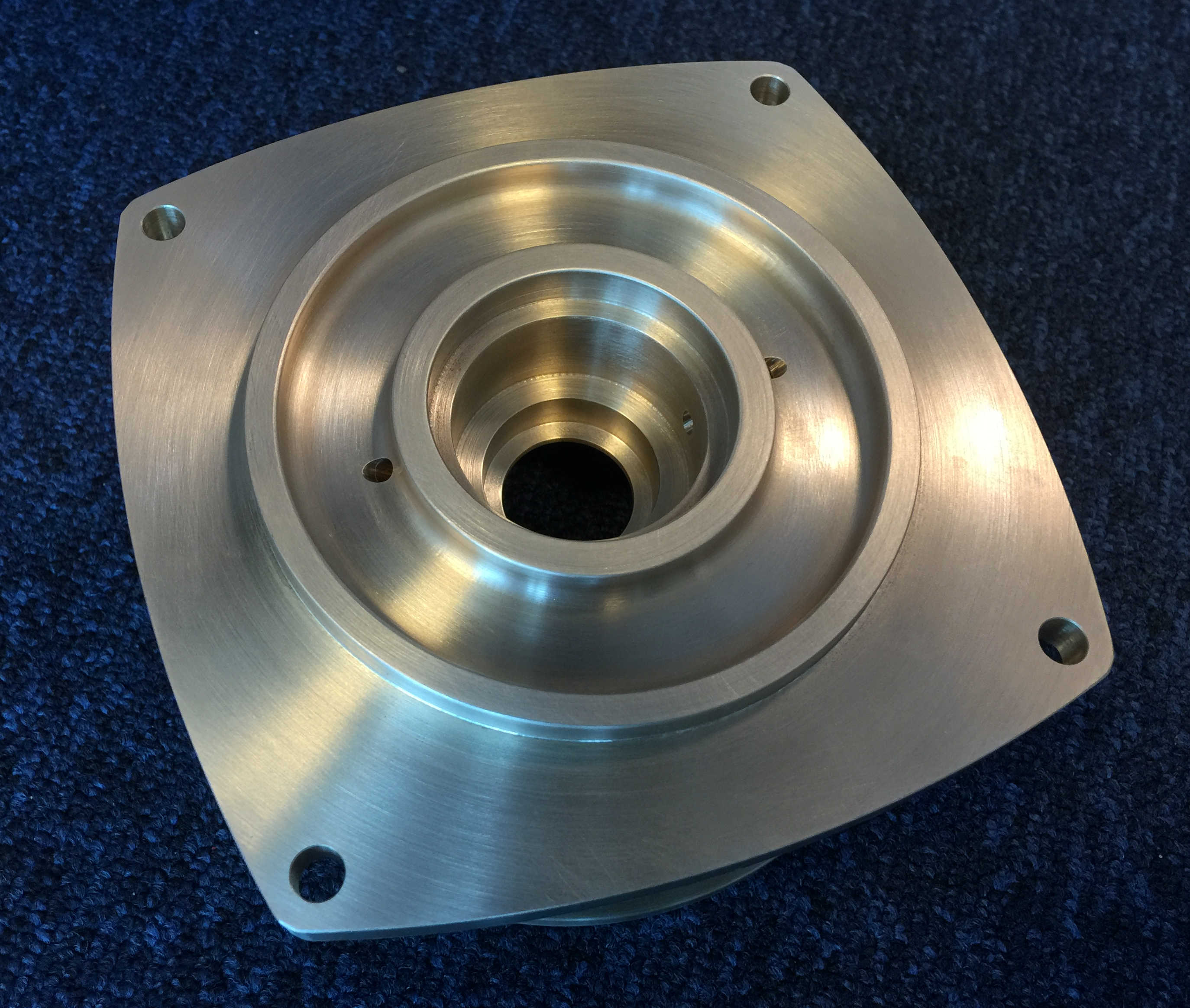

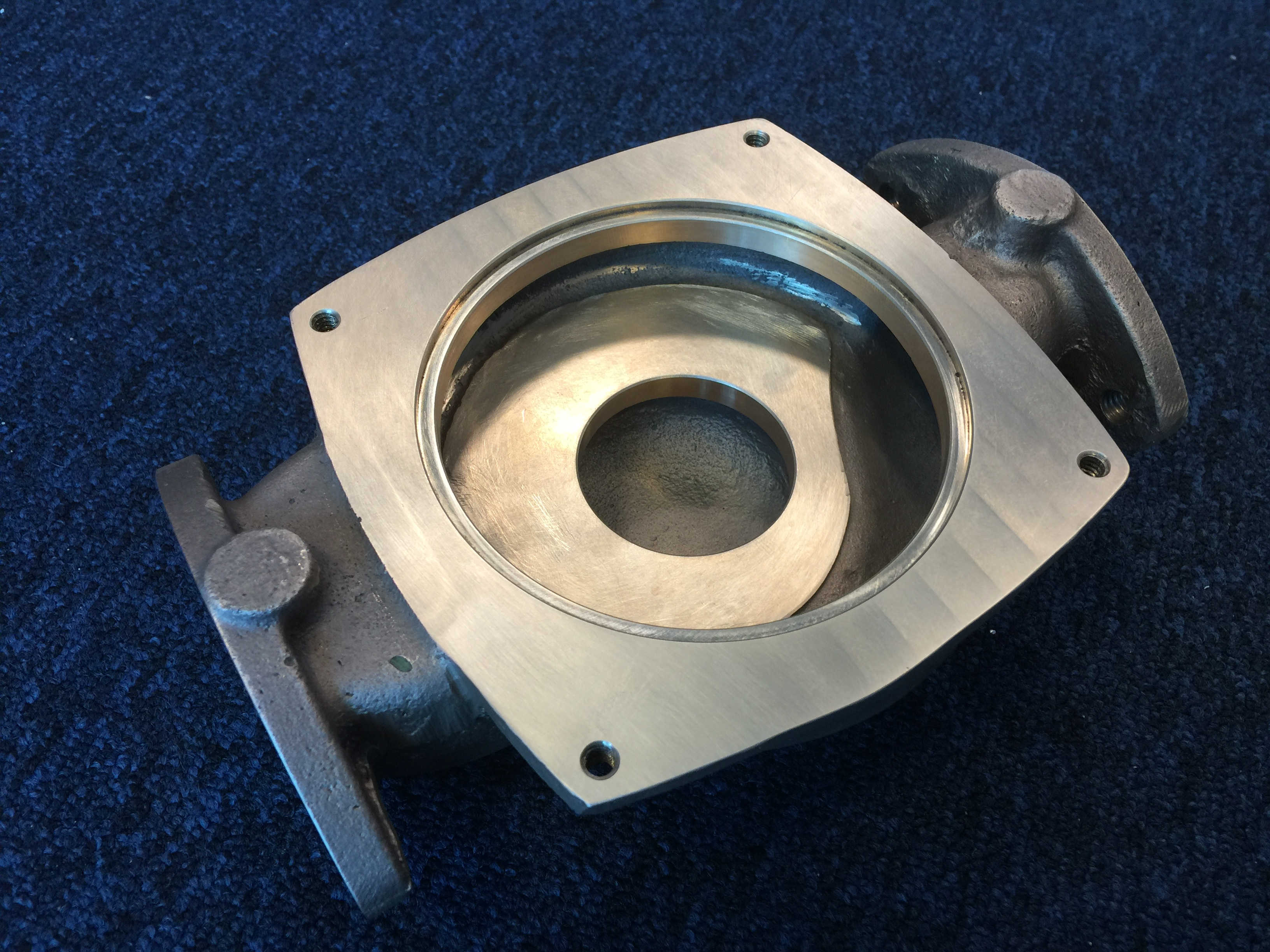

Marine Oil Pump

- The pump had been in service for a good number of years before efficiency began to drop to an unacceptable level.

- As the OEM for the pump was no longer in business our customer was unable to source spares.

- It would have been possible to swap the pump for a completely new unit but the customer didn’t want to have to change any of the current set-up and were concerned about the reliabilty of a new, unproven pump.

- KARM were able to scan and model the pump assembly and produce all of the required spares.

- KARM now supply all spares and will continue to do so for as long as the customer requires, making obsolescence a thing of the past!